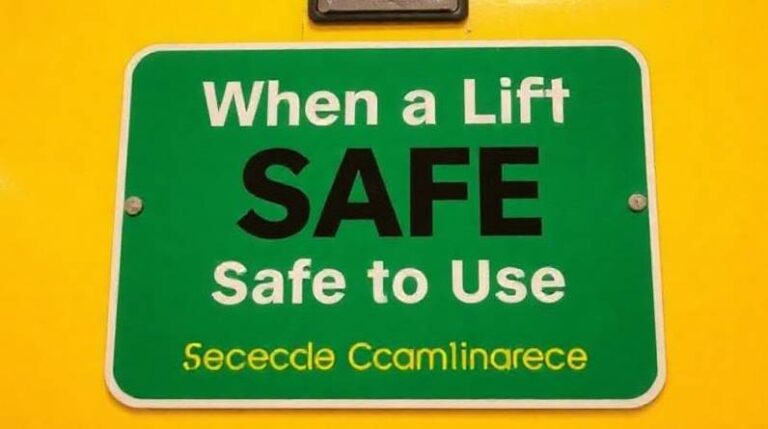

Elevators and lifts are more than just a convenience—they are critical infrastructure in workplaces, hospitals, homes, and public spaces. Each time a lift door closes, passengers trust that the system will deliver them safely to their destination. But how do you really know a lift is safe? The answer often lies in a simple but powerful indicator: this sign shows when a lift is safe to use.

While many articles highlight regulatory requirements and inspection routines, this guide takes a broader look at the human, technological, and operational perspectives behind lift safety signs. It explores not only what the signs mean but also why they matter in practice, how they influence public confidence, and what future trends could redefine lift safety worldwide.

What Does “This Sign Shows When a Lift Is Safe to Use” Really Mean?

At its core, the sign indicates that:

- The lift has been inspected and certified within the required legal timeframe.

- Load capacity limits are clear and enforceable.

- Emergency systems such as alarms, brakes, and communication lines are functional.

- The lift meets regional safety regulations (OSHA in the U.S., LOLER in the U.K., Dubai Municipality in UAE, etc.).

Think of it as a passport for safe operation—without it, you’re stepping into a system that may be overdue for inspection, poorly maintained, or even unsafe.

Why These Signs Matter More Than You Think

Most people glance past safety certificates, but their presence carries far-reaching implications:

- Public Reassurance – Shoppers, office staff, or hospital visitors gain confidence when they see proof of recent inspections.

- Legal Protection – Property managers who display compliant signage can demonstrate due diligence if an accident occurs.

- Operational Efficiency – Clear indicators reduce unnecessary downtime or hesitation, especially in fast-paced environments like logistics hubs.

- Cultural Impact – Visible safety signs build a “safety-first” mindset among employees and building occupants.

Key Components of a Lift Safety Sign

A proper lift safety sign is more than a date stamp—it’s a multi-layered assurance system.

| Component | Why It Matters |

| Last Inspection Date | Confirms recent safety check |

| Next Due Date | Ensures ongoing compliance |

| Inspection Agency | Shows accountability and authority |

| Certification Number | Allows record-tracking |

| Load Capacity | Prevents overloading risks |

| Emergency Contact | Provides quick response options |

Modern safety signs may also include:

- QR Codes for real-time verification online.

- Symbols and pictograms for universal understanding (✅ Safe, 🛑 Out of Order, ⚠️ Caution).

The Psychology of Lift Safety Signs

While regulations explain what must be displayed, few discussions explore the psychological effect of these signs:

- Reassurance in Anxiety-Prone Situations – People who fear elevators often scan for signs of safety. A visible, up-to-date certificate reduces stress.

- Behavioral Cues – Operators and users are less likely to overload or misuse lifts when signs clearly outline restrictions.

- Trust in Infrastructure – A missing or outdated sign creates doubt about the entire building’s safety culture, even beyond the lift itself.

In short, these signs are not just functional—they shape how people feel about using the lift.

Legal Requirements Around the World

Lift safety isn’t universal—inspection intervals and signage requirements vary globally:

| Country | Inspection Frequency | Safety Sign Display Required |

| USA | Every 12 months (OSHA) | Yes |

| UK | Every 6 months (LOLER) | Yes |

| India | Monthly in some states | Yes |

| UAE | Every 6 months (Dubai Municipality) | Yes |

This variation highlights the importance of local compliance. Building owners must know their jurisdiction’s rules to avoid penalties and protect users.

The Role of Technology in Lift Safety Signs

The future of lift safety is shifting from static certificates to dynamic systems:

- Smart Sensors – Detect overloads, malfunctions, or unusual vibrations.

- Digital Displays – Update inspection status in real-time, reducing reliance on manual paperwork.

- Interactive Safety Prompts – Some modern lifts require operators to acknowledge capacity limits before activation.

- Augmented Reality (AR) – Provides safety overlays via smartphones or AR glasses in industrial settings.

These innovations turn safety signs into live indicators, bridging the gap between human awareness and machine intelligence.

What Happens If the Sign Is Missing or Expired?

Ignoring or overlooking a lift safety sign can have severe consequences:

- Accident Risk – An overdue inspection may mean unnoticed mechanical faults.

- Legal Penalties – Non-compliance can trigger fines, lawsuits, or even criminal charges.

- Insurance Issues – Claims may be denied if an uncertified lift is in use.

- Reputation Damage – Tenants and visitors may lose confidence in the property.

Example: A manufacturing plant in the U.S. faced fines after OSHA audits revealed missing signs. After corrective measures and proper signage, accident rates dropped significantly.

Best Practices for Using and Maintaining Lift Safety Signs

To maximize their effectiveness, organizations should adopt a proactive approach:

- Strategic Placement – At eye-level, near lift entrances and inside cabins.

- Routine Updates – Replace outdated or faded signs immediately.

- Training Programs – Educate staff and tenants on what to look for.

- Custom Solutions – Multilingual or pictogram-based signs for diverse workplaces.

- Integration with Maintenance Logs – Ensure signs match inspection records for accountability.

A Real-Life Lesson: The Danger of Ignoring the Sign

Consider the story of a worker who used an uncertified lift in an older office building. The lift stopped abruptly between floors, trapping him inside without ventilation or emergency contact numbers. He was rescued after 40 minutes—shaken but safe.

This incident underscores why a missing or outdated sign isn’t just a bureaucratic issue—it’s a direct risk to human life.

Sustainability Meets Safety

As industries push for eco-friendly solutions, safety signage is evolving too:

- Digital certificates reduce paper waste.

- Durable, recyclable materials extend the life of physical signage.

- Cloud-based inspection records ensure transparency and easy audits.

Lift safety signs are moving from passive notices to sustainable, smart safety systems.

Final Thoughts: One Sign, Many Lives

The message “this sign shows when a lift is safe to use” is deceptively simple, but it carries profound weight. It is not only a matter of legal compliance but also of public trust, psychological comfort, and technological innovation.

Next time you enter a lift—whether in a hospital, shopping mall, or factory—take a second to glance at that small certificate. It may look ordinary, but it is one of the most important safety features of the entire building.

FAQs

Q1. What does the sign “This lift is safe to use” mean?

It confirms the elevator has passed its latest inspection, meets safety regulations, and can be used within the stated load and operational limits.

Q2. Where is the lift safety sign usually located?

It is typically found inside the lift cabin near the control panel or on the wall near the lift entrance, positioned at eye level for visibility.

Q3. How often are lifts inspected for safety?

Inspection intervals vary by country, but most regions require checks every 6–12 months. Some high-traffic or industrial lifts may need more frequent inspections.

Q4. What happens if the safety sign is missing or expired?

A missing or outdated sign suggests the lift may not be compliant or safe. Avoid using it and report the issue to building management immediately.

Q5. Who is responsible for displaying lift safety signs?

Building owners or property managers are legally responsible for arranging inspections and displaying valid, up-to-date safety signs.

Q6. Can a new lift be trusted without a safety sign?

No. Even brand-new lifts require official certification. The sign is the only reliable proof that the lift has been inspected and approved for use.

Q7. Do lift safety signs differ across regions?

Yes. For example, the U.S. requires annual checks, the U.K. mandates inspections every six months, while some regions in India require monthly certifications.

For more insightful articles and the latest updates, keep visiting Hacoo.